EEXI Simulation Demonstrator

Global efforts to reduce the environmental impact of the shipping industry have seen new measures by the International Maritime Organisation (IMO), come into force from January 2023, such as the Energy Efficiency eXisting Ship Index (EEXI), and Energy Efficiency Design Index (EEDI) for new designs.

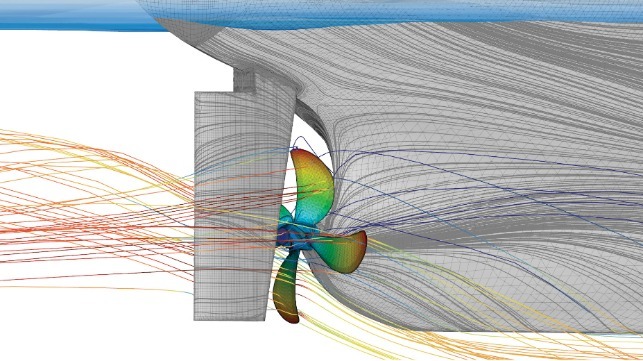

From 2022, the IMO accepts Computational Fluid Dynamics (CFD) as a means to provide the vessel reference speed needed in EEXI/EEDI calculations. There are many reasons why running a CFD programme is superior to utilising traditional towing tank methods. In addition to substantial time and cost savings, CFD benefits from running simulations in a 1 to 1 scale, removing any errors or uncertainties when applying scaling effects from model scale to full scale.

One of the default methods accepted by IMO for calculating the EEXI/EEDI reference speed is to use an empirical formula that considers the ship type and installed power. This is an unrefined procedure, plus this speed will be conservative since the formula includes a penalising margin factor. Thus, it is more beneficial to calculate a precise reference speed with CFD as this will aid compliance and makes the vessel more commercially viable.

Cape Horn Engineering specialise in EEXI/EEDI calculations based on high-fidelity RANS CFD and offer these in a very efficient and cost-effective manner, having developed validated workflows and Best Practice Guidelines in conjunction with a leading classification society (Lloyds Register). Their workflows comply with a strict set of directives and recommendations from the International Towing Tank Conference (ITTC) and the International Association of Classification Societies (IACS).

The ITTC recommendations are concerned with the “Quality Assurance in Ship CFD Application” and describe how the Validation and Verification (V+V) process must be performed. They also set the requirement for the organisations delivering the CFD results to formulate and document their own version of Best Practice Guidelines.

The IACS guidelines outline the process for determining the reference speed for use in the EEXI calculation. The guidelines establish a set of criteria which the CFD organisations need to fulfil for the “Demonstration of Qualification” and detail how the validation and calibration of the CFD results must be demonstrated and documented for each new project.

The Demonstration of Qualification requires that the CFD organisations have conducted Verification and Validation on a set of comparable ships and that they can demonstrate this with supporting documentation.

In general, the EEXI calculation consists of 2 phases; the Verification and Validation to determine a “valid correlation factor”, and the computation of the new speed-power curve for the EEXI certification at full scantling condition. The first phase is needed to assess the numerical and modelling uncertainty. Depending on the vessel, it can be conducted using existing measurement data from model tests or from sea trials, with sea trials being the preferred option. Sea trials are usually performed at draft ballast. The CFD simulations must be performed for at least one of the conditions documented in the sea trials, usually the one that is closest to the EEXI condition, for example for 75% MCR. The difference between the simulated results and the measured ones then must be assessed, to determine the ’modelling uncertainty’. This is also known as the “Validation” process. This difference will be used as a correlation factor to shift the speed power curve in the full loaded condition to be computed in the second phase.

At the same time, for the same condition, the spatial discretisation (mesh density) and the temporal discretisation (time step used to advance the simulations) must be varied systematically to determine the ’numerical uncertainty’. This process is also known as the “Verification” process. The spatial and temporal uncertainties are combined to form the total numerical uncertainty. The uncertainty from the sea trials also needs to be considered, and if the correlation between CFD and measurements fall within the combined numerical and experimental uncertainties, the solution is considered to be “valid” and the correlation factor can be used in the second phase (see Verification and Validation below).

After the V+V process is proved to be valid and the speed-power curve is determined, considering the correlation factor, the vessel reference speed “Vref” can be interpolated for use in the EEXI formula. This whole process must be documented following the IACS guidelines for submission to the classification society who will act as the “Verifier” and issue the corresponding EEXI certificate.

A similar process will be followed in case the vessel undergoes modification to improve performance, for instance by installing Energy Saving Devises (ESDs) like asymmetric stern bulbs, nozzles or fins in front of the propeller, fins in the propeller boss cap etc. The CFD V+V will be conducted for the same conditions in the sea trial, usually without the ESDs, and then using the same simulation setup, the EDS will be included to calculate the new, improved speed-power curve for the EEXI condition. Thus, CFD is the best way of assessing and demonstrating the savings to improve the EEXI certificate of vessels.

Cape Horn Engineering has experience demonstrating performance improvement using energy saving devices. Furthermore, specialising in Wind Assisted Ship Propulsion (WASP), using devices such as wing sails, suction sails, Flettner rotors, or any other wind-powered devices. In the case of WASP, the IMO guidelines dictate that in cases that more than one device is installed on deck, the forces produced by the devices should consider their interactions. Cape Horn Engineering specialise in computing such interaction models, making use of advanced machine learning techniques.

The products and services herein described in this press release are not endorsed by The Maritime Executive.