Wind-to-Whiskey: Green Hydrogen Could Power Scotland's Distilleries

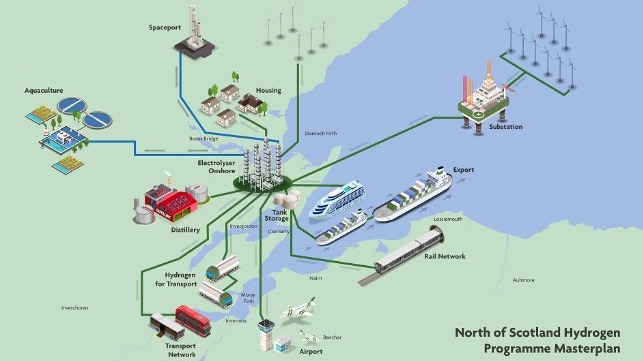

The Port of Cromarty Firth is launching plans for a "green hydrogen hub" for Scotland's whiskey industry, turning offshore wind power into thermal heating power for distilleries.

Green hydrogen is created using electrolysers powered by electricity from renewable sources, splitting water into hydrogen and oxygen. The power for Cromarty Firth's facility would be supplied from current and planned future wind farms off the coast.

Some of the initial customers would be Scotland's famed distilleries. A feasibility study will begin this month and is due to be completed in June, with private funding from ScottishPower, Pale Blue Dot Energy, and whiskey makers Glenmorangie, Diageo (owner of Johnnie Walker) and Whyte & Mackay.

The delivery of green hydrogen to Glenmorangie, Whyte and Mackay and Diageo would allow them to decarbonize the heating of their distilleries and maltings, which are near to the Cromarty Firth. Their plan is to use the hydrogen as a substitute for fossil fuel for their boilers, producing steam needed for the distillation process.

“In the short term, we have a number of local partners with vast experience in hydrogen, distilling and utility provision who want to decarbonise their operations," said port CEO Bob Buskie. "And in the long term, there is a huge opportunity to decarbonize Highland industry, transport and heat, as well as exporting green hydrogen to other parts of the UK and mainland Europe, which doesn’t have the same offshore wind capacity as Scotland.”

Up to 15 new offshore wind sites are due to be developed off Scotland in the coming years, and many will be just off the Cromarty Firth. The port says that this source of power - combined with deep-water berths and a location at the end of the gas grid - makes the location ideal for

that matters most

Get the latest maritime news delivered to your inbox daily.

The process of manufacturing hydrogen from electrical power entails loss, with electrolyzers delivering a conversion efficiency rate in the range of 60-70 percent. However, electrolyzers can be used to soak up extra output from wind farms when the wind is blowing strong, capturing power that would otherwise go unused.

Because of the relatively low conversion efficiency, many analysts suggest that green hydrogen is not the most efficient option for heating when electricity can be used directly. In contrast to electrolyzers, electric steam boilers are 95-100 percent efficient, without the infrastructure needed to convert electricity into hydrogen as an intermediary step.