Port of Antwerp Orders Hydrogen-Powered Tug

The Port of Antwerp has commissioned the construction of the world's first hydrogen-powered tugboat, and there will be no fuel cells on board. The design is powered by combustion engines that run on hydrogen in combination with diesel. These will be ultra-low-emissions engines meeting EU Stage V, making them among the cleanest on the market, according to the port.

The new tug builds on technology popularized by Compagnie Maritime Belge (CMB), the storied Antwerp-based shipping company held by the Saverys family. In 2017, CMB debuted a small passenger catamaran powered by hydrogen-fueled Volvo Penta diesel engines. The new catamaran - Hydroville - is in service as a small ferry for CMB's own staff along the River Scheldt in Antwerp. It runs on hydrogen sourced locally by industrial supplier Air Liquide in Lillo, Belgium.

CMB has a growing portfolio of hydrogen-powered projects, like a hydrogen-powered wind farm service vessel for Windcat and a hydrogen-powered ferry with Tsuneishi Facilities & Craft Co. It is also launching its own engine manufacturing joint venture with ABC, called BeHydro, which will begin marketing a line of medium-speed hydrogen engines of up to 2.8 MW next year. The Hydrotug will be among the first vessels powered by BeHydro engines.

"With this scoop we want to further pave the way for alternative fuels, such as hydrogen, to help shape the transition to alternative and renewable energy sources. As Port of Antwerp we set a good example ourselves by taking a big step in the greening of our own tugs," said Jacques Vandermeiren, Port of Antwerp CEO.

Variable results

The CO2 profile of hydrogen fuel is highly dependent on its source: it has the potential to radically decrease shipping's carbon footprint, but also the potential to increase it.

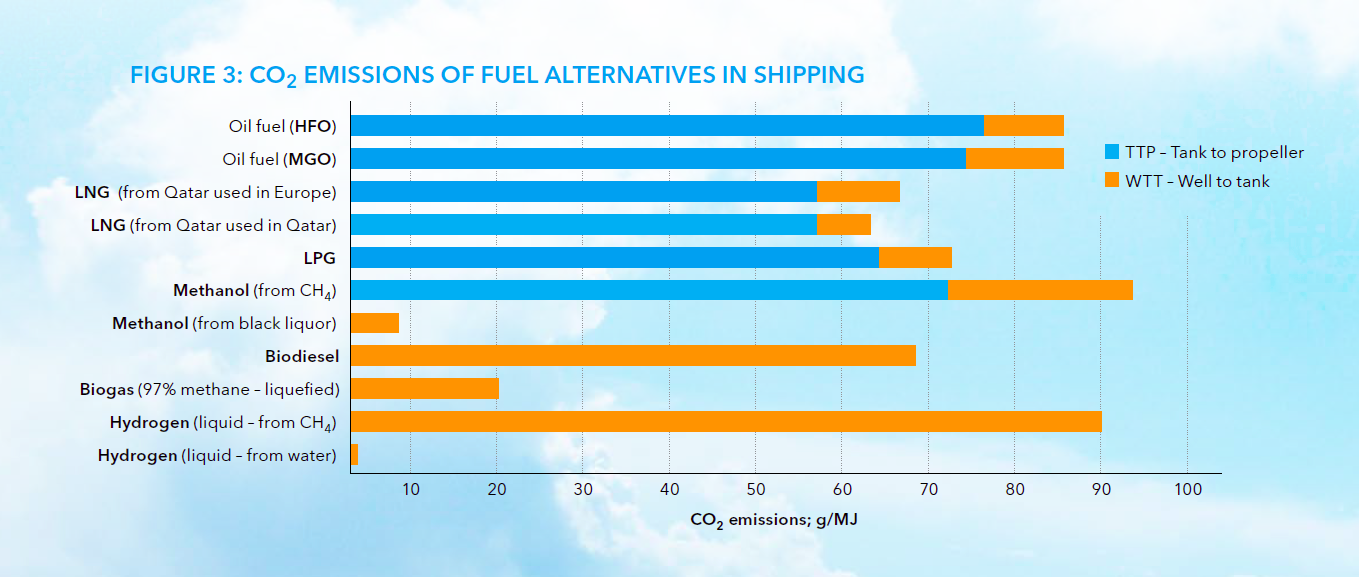

Mass-market hydrogen is among most carbon-intensive marine fuels available today, generating even more CO2 than bunker fuel, according to a recent study by DNV GL. The great majority of commercial hydrogen is made in an industrial process using a feedstock of natural gas, oil or coal, releasing large quantities of CO2 at the plant site. (At an additional cost, carbon capture at the plant could one day reduce the greenhouse gas footprint of this fuel source.)

Hydrogen produced using electrical power can be a near-zero-emissions fuel, though costs are currently high. This method uses electricity to split water into hydrogen and oxygen. If the electrical power comes from a renewable source, the fuel has an exceptionally small CO2 emissions profile - the smallest of any option examined in the study (below).

Additional small-scale sources exist, like hydrogen created as a byproduct of chlorine production. As an example, the Solvay chlorine plant in Lillo, Belgium has installed a stationary hydrogen fuel cell to take advantage of the excess hydrogen produced on site.

that matters most

Get the latest maritime news delivered to your inbox daily.