Improperly Installed Fuel Line Caused Engine Room Fire on APL Boxship

The NTSB has determined that a loose pipe fitting caused the serious engine room fire and blackout aboard the boxship President Eisenhower off California last year.

On April 26, 2021, the second engineer on President Eisenhower installed a new section of steel tubing for the fuel oil return for the main engine, replacing a section that had developed a pinhole leak. The next day, at 1900 hours, the Eisenhower departed the Port of Los Angeles for Oakland via the Santa Barbara Channel. After ramping up the engine load program for the transit, the first and second engineers completed a walkaround. All looked good, and at 0053 they left the engine room for the night, leaving it in "unattended" status.

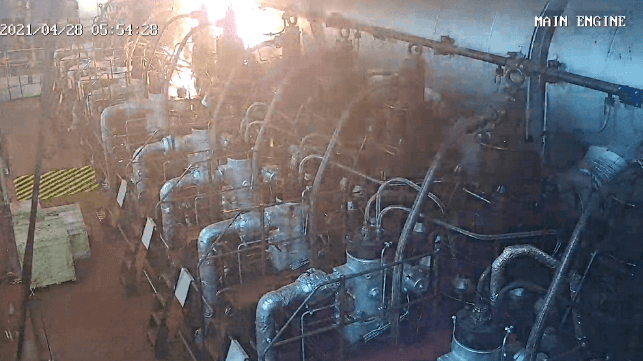

One hour later, at 0154, an AB on the bridge wing noticed smoke coming from an engine room hatch. At about the same time, a fire alarm activated for the engine room. Looking at the CCTV monitor for the space, the captain and third mate confirmed that there was an active engine room fire in progress. The crew followed procedure, shutting down ventilation systems, closing fuel supply valves, switching to the emergency generator, and suiting up firefighting teams.

As a first attempt, the crew sent in an attack team with a hose to try and quell the fire, but they quickly determined that it was "too much" to fight and retreated. The captain ordered all ventilation hatches to the space closed and the fixed firefighting CO2 system activated. This was completed at about 0223 hours. After flooding the space with CO2, they allowed the fire-affected areas to cool throughout the morning to ensure that there would be no reflash.

The fire left the vessel without propulsion, and as the day progressed, President Eisenhower drifted closer to shore. A response tug arrived on scene at about 1400 and helped move the stricken ship further out into the channel; at her closest approach to land, she was about 3.5 miles from shore. A marine firefighting team came aboard and helped the crew verify that the blaze was fully extinguished, and the ship was towed back to the Port of Los Angeles for repairs.

After the fire, the team leader for the salvor’s marine firefighting team told NTSB that the vessel’s crewmembers were “very well trained” and that that their use of the fixed CO2 system to extinguish the fire “was just textbook perfect.”

that matters most

Get the latest maritime news delivered to your inbox daily.

In a post-casualty examination, investigators found that a compression fitting on the end of the tubing had come fully disconnected, resulting in a spray of diesel fuel. Footage from the vessel's camera system showed that the diesel spray began fully 30 minutes before the fire started. The diesel hit an uninsulated exhaust system component, sparking a blaze.

NTSB concluded that the improperly-installed compression fitting and the uninsulated exhaust system component were the probable causes of the fire. It added that the fitting's failure might not have resulted in a fire if the vessel had had a rapid oil leak detection system, which could have spotted the fuel spray and sounded an alarm before it ignited.