Ammonia and Methanol Designs Advance with Approvals from ABS

The shipping industry continues to seek a broad range of advanced designs that will help it to move towards the goals of reducing emissions, transitioning to alternative fuels, and achieving zero-carbon operations. Naval architects, shipyards, and shipping companies are all pursuing designs supported by the classification societies evidenced by the announcement that ABS has just awarded two more Approval in Principle (AIP) for designs employing ammonia and methanol.

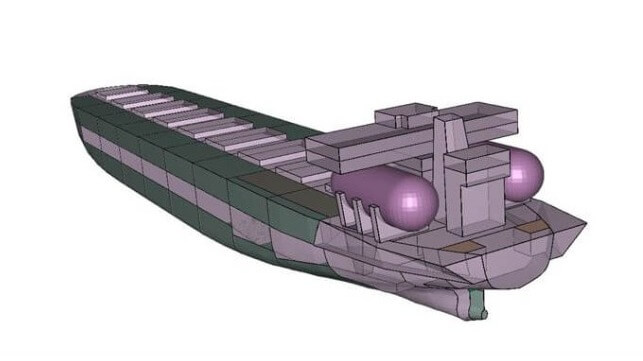

Anglo-Eastern Technical Services (AETS), a technical consultant specializing in newbuildings, conversions, naval architecture, plan approvals, inspections, and surveys, developed designs for an ammonia-fueled Newcastlemax bulker that was granted an AIP by ABS. The classification society calls it an innovative design.

The concept is for a dual-fuel vessel that sacrifices no cargo space according to ABS. The design uses deck-mounted IMO Type C tanks under the accommodation block on each side of the vessel. AETS reports that its focus was on a system for retrofit to existing vessels as well as ammonia-fueled and ammonia-ready newbuildings.

“The transition to alternative fuels is an unavoidable part of our industry’s journey towards net-zero propulsion technologies,” said Bjorn Hojgaard, CEO of Anglo-Eastern Univan Group. “Having in place advanced alternative ship designs of equivalent safety as conventional vessels will facilitate the rate of adaptation.”

Ammonia is one of the promising alternatives that continue to make advancements as a potential marine fuel. At the same time, others in the industry are pursuing methanol which appears to potentially be on a faster track to widespread availability for the maritime industry.

ABS also recently awarded an AIP for a methanol fuel-ready medium range tanker design. This AIP is the culmination of a five-month joint development project between ABS and K Shipbuilding in South Korea to evaluate a range of aspects including storage, bunkering, and issues caused by methanol’s corrosive properties. The basic design was reviewed in accordance with the principles of the ABS Guide for Gas and Other Low-Flashpoint Fuel Ready Vessels. When built, the vessel will be able to claim the ABS Methanol Fuel Ready Notation.

that matters most

Get the latest maritime news delivered to your inbox daily.

“The AIP for methanol fuel-ready medium range tanker design is just the beginning,” said Mr. Tae-Hyun Koh, K Shipbuilding Chief Technology Officer. “Now we are conducting the research and development on eco-friendly fuel-powered vessels such as LPG, ammonia, and hydrogen to prepare for the future, and we will continue this R&D work.”

The awarding of this AIP was also notable as it marked the next step in the restoration of the former STX Korea operations. Once one of the leaders in the industry, STX collapsed into a financial crisis that saw its global network dismantled. Last summer, a new investor group purchased the surviving operation in South Korea rebranding it as K Shipbuilding and announcing plans to restore the company as an innovator in shipbuilding.