Video: First 3D Printed Ferry Begins Trials in Dubai

Dubai’s Roads and Transport Authority is promoting its new project which developed what it calls the world’s first ferry manufacture red using 3D printing technology. Created with an international private partnership they are saying the ferry is less costly and more ecologically friendly in its production and will be operated entirely with battery power.

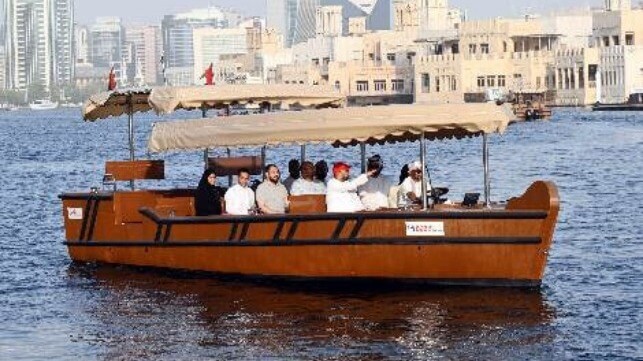

The project seeks to produce a new generation of “abra,” a traditional vessel used to ferry passengers along the Dubai Creek. The waterway accesses the heart of the city and is traveled by more than 12 million people annually.

The project has several unique achievements, including the longest single hull printed using 3D printing technology. The vessel is 36 feet (11 meters) in length and can transport up to 20 people. It also uses a stiff outer skin known as a monocoque structure to create the form of the vessel.

Propulsion for the vessel is fully electric. It has two 10-kilowatt motors powered by lithium batteries.

The trial operation of the world's first electric abra manufactured using 3D printing technology.

— RTA (@rta_dubai) July 14, 2024

This abra, which can carry 20 passengers, features numerous technical attributes, including the longest monocoque structure created using 3D printing technology, measuring 11 metres… pic.twitter.com/2VldjMeinw

The abra was manufactured by Al Seer Marine Company in Abu Dhabi in cooperation with international companies. Mitsubishi provided the materials used in manufacturing and printing, while Siemens supervised the programming and calibration of the printer. Torqeedo supplied the electric motors, and the Tasneef Company supervised the manufacturing and the vessel’s compliance with safety standards.

The vessel will be used in a pilot project during which the performance will be monitored. They look to compare the vessel with the current generation of fiberglass vessels used to ferry passengers in Dubai. The goal is to develop a fleet of the new vessels.

that matters most

Get the latest maritime news delivered to your inbox daily.

The Road and Transport Authority reports it expects the manufacture time of the abra can be reduced by 90 percent using 3D printing, Manufacturing costs are projected to be reduced by 30 percent versus the fiberglass vessels. In addition, operating and maintenance costs are also expected to be reduced by 30 percent.