A Radical Solution to the Challenges of Slow Steaming

Slowing down vessels may be the most direct way to cut fuel consumption and emissions, but it is not without its issues. A new solution from Wärtsilä, Fit4Power, offers an alternative that tackles many of the challenges of running large engines on low load, while monitoring since the first installations in October 2022 reveals just how effective radical derating can be. Andreas Wiesmann, General Manager of Strategy and Business Development for 2-stroke Engine Services at Wärtsilä Marine, explores the potential of the technology, leveraging broad industry expertise to demonstrate its transformative effect on the shipping industry.

Slow steaming is a crucial component of emissions reduction strategies for vessels that do not need speed to cater to their markets, such as those on scheduled routes as opposed to spot trades. One of the key drivers is IMO’s Carbon Intensity Indicator (CII), which demands annual improvements in operational efficiency from vessels based on reported fuel consumption and voyage data. Wärtsilä analysis shows that, without modifications or operational measures, more than 80% of the global merchant fleet could fall into the ‘D’ and ‘E’ CII ratings by 2030, requiring mandatory corrective action.

Balancing speed and emissions

Slowing vessel speed therefore offers a straightforward option for cutting fuel and emissions without investing in new efficiency technologies. However, operating at low loads well below those for which they were designed is not an ideal scenario for engines. As a result, an overall reduction in fuel consumption and emissions can carry a significant penalty in efficiency. Less fuel is used overall, but more fuel is needed to generate an equivalent power output.

The practice leaves operators with another cost problem: the maintenance requirements of a big engine with the power output of a small engine. In addition, because engines that run outside their optimal load are more prone to wear, those costs can also increase with slow steaming. The result is an oversized engine for which operators are paying oversized maintenance and fuel bills, without being able to take advantage of the surplus installed power.

Further, slow steaming does not necessarily help comply with design efficiency regulations. The IMO’s Energy Efficiency Index for Existing Ships (EEXI), for example, does not directly demand that less fuel is used but instead that available power is limited. That means using mechanical or software-based measures to ensure that the lower power is maintained (with an exception for emergencies). Those limitation solutions come at a cost and add complexity to the engine configuration.

A radical approach

When Wärtsilä applied itself to the inherent problems of slow steaming, it came up with a radical solution. If vessel operators can sail at slower speeds, the most efficient way to do it would be to reduce the size of the engine. Thermodynamically, running a smaller engine at higher loads will always be more efficient than running a bigger engine at low loads due to relatively lower mechanical losses and a more optimal air-fuel mix in the combustion chamber.

While this principle has guided engine selection for newbuild vessels for decades, until recently it had little value for ship operators with existing vessels. It was not viable to reduce the size of an engine already installed. The unique proposition behind Wärtsilä’s radical derating solution for two-stroke engines is that it makes reducing the size of the engine achievable.

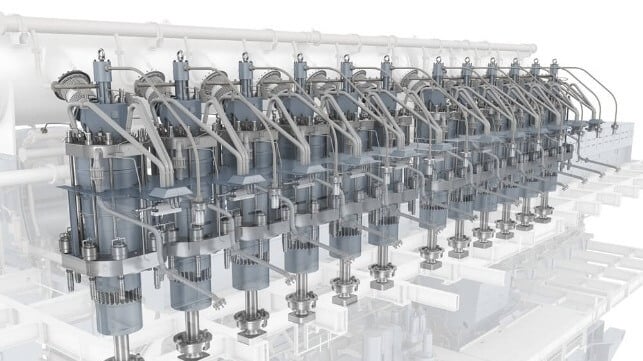

The advanced retrofit solution enables ship owners to reduce the bore size of two-stroke engines by 25%, enabling the vessel to reduce speed while the engine runs at optimal loads, with outstanding fuel and combustion efficiency. This cuts both fuel consumption and greenhouse gas emissions. The bore size reduction is achieved with no changes to the engine frame and only matching part replacements on turbocharger installations. This simplifies the conversion process, limiting it to cylinder, piston and fuel injection components alongside an update to the engine automation system.

While Fit4Power is a significant project, it does not represent what IMO classes a ‘major conversion’, meaning that the derated engine does not need a new nitrogen oxide (NOx) certification. The engine’s original tier rating can be maintained and is confirmed by Wärtsilä after the project using its approved ‘shop test at sea’ methodology. This process avoids the time-consuming and costly process of running an equivalent engine on a testbed.

A retrofit project of this scale is an exercise in teamwork. Across the 17 vessels already installed by the end of the first quarter in 2025, Wärtsilä has developed close relationships with partners across the supply chain and with repair yards. The retrofit execution has been refined over time, allowing the current conversion to be completed in less than four weeks – comparing favorably to other technology installations and allowing operators to plan their regulatory compliance less than a year into the future.

Staying ahead of the curve

It is already clear that the benefits of the radical derating are well worth the effort. An engine retrofitted with the Fit4Power technology can deliver annual fuel savings of up to 2,000 tons and a reduction in CO2 emissions of 6,400 tons. In financial terms, this translates to potential yearly savings of two million euros, or more, in operational expenses, based on current fuel costs and carbon levies. Add to this an annual savings in parts, and the economic case for radical derating becomes compelling.

Fit4Power can cut fuel consumption and emissions by 10-15%. Across 17 vessels retrofitted since late 2022, Wärtsilä has saved operators a total of more than 25,000 tonnes of fuel, translating to 80,000 tonnes of CO2 emissions or more. Further translated into regulatory compliance terms, this buys operators a further three to five years of compliance with CII, giving them time to plan the next stage of their decarbonization investment strategy.

However, derating is more than just an interim measure. By making engines smaller and more efficient, operators are setting a new efficient baseline for the operation of their vessels, as well as paving the way for incremental steps towards decarbonization. For example, future conversion of the engines for methanol, LNG or ammonia fuel, using Wärtsilä’s Fit4Fuels platform, will enable the use of zero- or near-zero emissions fuels, and because the engine is already running at optimal efficiency, the cost of those expensive fuels will be minimized.

Slowing the speed of vessels can be a game-changing strategy as operators seek to reduce emissions. But slowing down the vessel need not mean slowing down the engine and all the inefficiencies that come with it. With Fit4Power, operators can sail full steam ahead into a future of lower emissions.

Andreas Wiesmann is General Manager of Strategy and Business Development for 2-stroke Engine Services at Wärtsilä Marine. This article is brought to you by Wärtsilä Marine.

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.