Op-Ed: Digitalization Can Help Revitalize U.S. Shipbuilding

Shipbuilding efficiency is vital if the U.S. is to rejuvenate its maritime capabilities, says Mikko Forss, Executive Vice President of NAPA, a maritime software company.

SHIPS for America

SHIPS for America

The U.S. has set out clear ambitions for a shipbuilding and shipping renaissance. Targets were outlined in the Shipbuilding and Harbor Infrastructure for Prosperity and Security (SHIPS) for America Act introduced to congress in 2024, and while it remains to be seen if it will be passed into law, it does have bipartisan support.

As well as highlighting the need for a new National Maritime Strategy, the SHIPS for America Act establishes a Strategic Commercial Fleet Program, which aims to increase the U.S.- flagged international fleet by 250 ships in 10 years and facilitate the development of a fleet of domestically built vessels that are commercially and competitively operated.

The SHIPS for America Act also introduces financial incentives for U.S. shipyard modernization and domestic shipbuilding by creating a tax credit of up to 40.5% for investments to construct, repower, or reconstruct eligible oceangoing vessels in the U.S., and a 25% tax credit for the modernization of qualified domestic shipyards.

In a similar vein, US President Donald Trump said in March 2025: “To boost our defense industrial base, we are also going to resurrect the American shipbuilding industry, including commercial shipbuilding and military shipbuilding. And for that purpose, I am announcing tonight that we will create a new office of shipbuilding in the White House and offer special tax incentives to bring this industry home.”

Shipbuilding efficiency

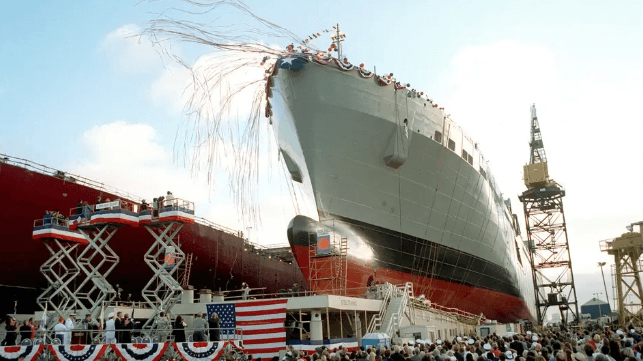

The U.S. has a proud history of world-leading shipbuilding, from the Liberty ships of World War II to today’s naval powerhouses. There’s now a renewed opportunity to channel that same industrial spirit into the digital age and be a global leader in shipbuilding innovation. To ramp up production, the focus must be on modernizing and scaling shipbuilding capabilities with a resolute focus on efficiency in concept development, design maturation and production.

The clearest path to accelerating domestic capabilities once again is by adopting proven best practices from shipbuilders around the world. Digitalization has played a pivotal role in ensuring efficiency, scalability and modernization of shipbuilding across both Europe and Asia, however, adopting digital shipbuilding tools comes with important caveats.

Digitalization, if done correctly, can break down silos and facilitate collaboration between shipowners, operators, shipyards, naval architects, engineers, academia and class societies. It can reduce inefficiencies in communication between various entities and enable more design iterations in less time. Done wrong, conversely, fragmentation and delays can result.

The nature of shipbuilding is engineer-to-order, which means considerable engineering efforts are required for every novel design. Unlike other industries where prototyping and series production can enhance the final product and reduce per-unit engineering costs, shipbuilding must meet various conflicting requirements and regulatory standards in a multidisciplinary field, necessitating accurate design on the first attempt. This is especially true in the initial stages of design, where key project management and engineering decisions will impact the overall safety, cost and efficiency of the entire project.

Providing the various stakeholders involved in the ship design process the means to access a consistent digital ecosystem, through a comprehensive set of interoperable digital tools, promotes consistency, efficiency, and optimization from concept to class approval to delivery and life-cycle management.

Digital shipyards

Digitalization provides the means for shipyards to do more with less. For smaller and mid-sized shipyards, where skilled labor can be hard to come by, efficiency isn’t just an advantage – it’s a necessity.

Insights from around the world shows that attracting new talent to the shipbuilding industry can been difficult amid rapid population declines, as seen in Japan and Korea. In Korea, the problem has been particularly acute in the past two years, since newbuilding work resumed after the lifting of COVID restrictions. But the situation has its roots in the layoffs that followed the 2014 market downturn, when the workforce was halved from approximately 203,000 workers to around 92,000.

Digital technology can help alleviate recruitment challenges on two fronts: by removing duplicated tasks to enable engineers and naval architects to maximize their productivity, and by making the sector more attractive to younger generations. Technologies such as artificial intelligence, metaverse, and AR/VR/MR have the potential to increase efficiency and attractiveness even further, as we are witnessing a paradigm shift in our society regarding how we live, work and interact – which also impacts shipbuilding.

Going forwards, the digital technology revolution unlocks a world of opportunities for shipyards to be more efficient with scarce resources, from creating new value from replacing 2D based methods with smart 3D models to digital twins to production simulation. This enables shipyards to prevent expensive errors during the downstream construction process through digital continuity by integrating computer-aided design (CAD), computer-aided engineering (CAE), and product data management (PDM) workflows using best-of-breed domain solutions.

Revitalizing U.S. shipbuilding is an opportunity to recapture the industry’s innovative and industrial spirit. Beyond strategic policymaking and investments, it will require a heavy focus on shipbuilding efficiency on a practical level. Effective digital transformation that promotes efficiency, innovation, and collaboration from shipyard to sea is key.

By combining the legacy of American industrial ingenuity with global best practices, the U.S. shipbuilding industry can benefit from proven methods, without the cost of lengthy development processes. Ultimately, by embracing innovative digital solutions and fostering collaboration across the value chain, the U.S. can not only enhance its shipbuilding capabilities but also set the industry on a course towards a sustainable and prosperous future.

Mikko Forss is Executive Vice President of NAPA, a maritime software company.

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.