Construction Study Starts for Larger, Elevated Pressure LCO2 Carrier

As efforts continue to develop the anticipated carbon capture and transport market for storage, a new project continues to advance a promising technology called Elevated Pressure which could be more efficient and less costly for LCO2 transport. Japan’s NYK Group and its partnership Knutsen NYK Carbon Carriers reported they will conduct a joint “constructionability study” toward the goal of developing the new carrier.

“While CCS is still in its developmental stage in terms of technology and market structure, the joint study of the LCO2-EP terminal-to-terminal vessel with KNCC and NYK is an important step for us to bring one of the viable options to the market,” said Tomoaki Takahira, Director, Chief of Design Division for Nihon Shipyard, a joint venture for ship design and sales between Imabari Shipbuilding Co., Ltd. and Japan Marine United Corporation. “In addition to medium-pressure and low-pressure vessels, we will continue to study the construction of LCO2-EP vessels to contribute to the establishment of the CCS value chain.”

NYK and Knutsen Group of Norway launched a joint venture company at the beginning of 2022 for the commercial development of liquified CO2 marine transport and storage. Knutsen has developed innovative technologies that would allow the transport of LCO2 at ambient temperatures.

Earlier this year, Knutsen NYK Carbon Carriers working with NYK and JX Nippon Oil & Gas demonstrated a technology based on the isenthalpic expansion cooling and liquefaction process which utilizes the characteristics of the elevated pressure method that stores and transports liquefied CO2 at ambient temperature. They emphasize the technology has the potential to be more efficient than conventional liquefaction conditions and methods and requires up to 20 percent less energy. They point out the technology would be more compact.

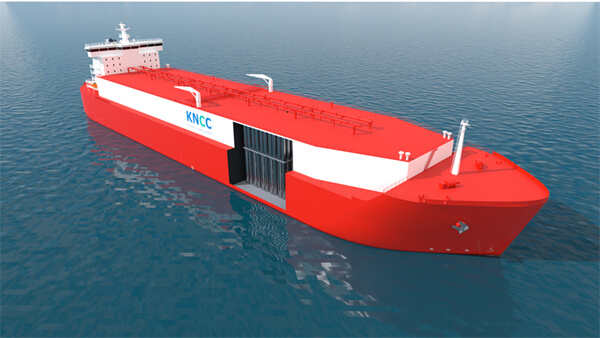

Cutaway shows the innovative storage which would make the vessel easier to build and more efficient (KNCC)

Among the benefits they highlight of the EP technology is that it provides a greater temperature safety margin than either medium or low pressure from corrosive liquids. They also report it would require 50 percent less energy than medium-pressure shipping and 70 percent less than low-pressure while delivering LCO2 much closer to injection conditions.

The study is exploring a 40,000 cbm terminal-to-terminal LCO2 vessel using EP technology.

“The innovative design of the LCO2-EP Cargo Tanks features vertical cylinders that can be mass-produced through automated processes using standard materials. This may optimize and reduce the construction time,” explains Oliver Hagen-Smith, CEO of Knutsen NYK Carbon Carriers. “The modular design potentially allows more shipyards to participate, utilizing existing facilities and infrastructure, which broadens industry engagement and enhances efficiency. We are confident that this study will bring significant benefits in cost-effectiveness, quality, and scalability to the maritime construction sector.”

The first dedicated LCO2 carrier Northern Pioneer is smaller in capacity and uses a low temperature tank (DSIC)

that matters most

Get the latest maritime news delivered to your inbox daily.

Currently, there is only one dedicated LCO2 carrier completed, the Northern Pioneer, which was delivered last week for Norway’s Northern Lights project. Built in China, the vessel is the first of four and each will have a capacity of 7,500 cbm. Each is equipped with two full-pressure C-type liquid cargo tanks made of special materials for transporting carbon dioxide, with a maximum bearing pressure of 19barg and can withstand low temperatures of -35 ?. They are designed to transport captured CO2 from Northern Europe to the holding and processing plant in Norway before being pumped through pipes to storage under the North Sea.

The industry continues to look for larger-volume vessels that could be used over longer distances. It is anticipated to be a new large segment of the shipping industry that will be developed over the remainder of this decade as storage is the solution for hard-to-abate industries.