In-Situ Machining Eight Crankpins in 14 Days

24/7 REPAIR EFFORT RESTORES MIRRLEES KVSS M16 V-TYPE MAIN ENGINE

During a routine maintenance inspection on one of its main engines, a British Columbia ferry operator discovered that the crankpins were in very poor condition. The owner contacted Goltens to perform an inspection on the 38-year-old engine and propose a repair.

Goltens performed a full inspection of the crankshaft and determined that the running surfaces of the crankpin journals were in very poor condition from years of wear. As no casualty had occurred, shaft straightness and hardness were both found to be within acceptable tolerances. Inspection of the main journals also revealed no damage.

Goltens reported the condition of the shaft to the owner and proposed machining the crankshaft in-place to restore it to service. Due to the demanding operational schedule of the vessel, the owner requested Goltens work around the clock to repair the engine.

Goltens sent two teams of in-situ crankshaft machining specialists to Canada to complete the repairs as quickly as possible.

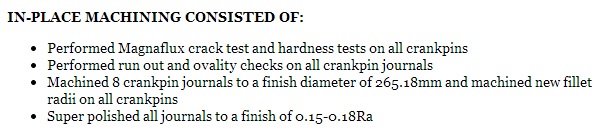

CRANKSHAFT MACHINING RESULTS:

CRANKSHAFT MACHINING RESULTS:

Working around the clock, Goltens completed this job within 14 days onboard.

Additionally, Goltens supplied the undersized bearings to the customer and the vessel's crew took on the job to rebuild the engine and return it to operation.

The products and services herein described in this press release are not endorsed by The Maritime Executive.