Shell Prepares for the World's Heaviest Lift

Next summer, the first Brent topside is due to be removed and taken to shore for dismantling and recycling. It will involve the heaviest lift ever to be carried out at sea – marking yet another milestone for a project that has set the benchmark for engineering feats in the North Sea.

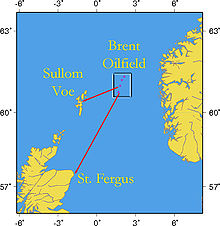

The Brent field is an oil and gas field located in the North Sea, 186 kilometers (116 miles) north-east of the Shetland Islands, Scotland, at the water depth of 140 meters (460 feet). The field, operated by Shell U.K., was once one of the most productive parts of the U.K.’s offshore assets but has reached the stage where production is no longer economically viable.

The field includes four large platforms: Alpha, Bravo, Charlie and Delta. The four topsides have a combined weight of over 100,000 tons, and the infrastructure includes three concrete gravity base structures of 300,000 tons each, 17,000 tons of steel jacket, 103 kilometers of pipelines, 140 wells and 64 oil storage cells each taller than Nelson’s Column and each with the capacity of four Olympic-size swimming pools. Alpha is a steel jacket, and Bravo, Charlie and Delta are concrete gravity base structures.

The field includes four large platforms: Alpha, Bravo, Charlie and Delta. The four topsides have a combined weight of over 100,000 tons, and the infrastructure includes three concrete gravity base structures of 300,000 tons each, 17,000 tons of steel jacket, 103 kilometers of pipelines, 140 wells and 64 oil storage cells each taller than Nelson’s Column and each with the capacity of four Olympic-size swimming pools. Alpha is a steel jacket, and Bravo, Charlie and Delta are concrete gravity base structures.

Decommissioning of the field has been divided into five different stages. The first stage involving identification of viable decommissioning options has already been completed. The second stage was completed in 2011 and involved the selection of the final concept for decommissioning. The third stage is currently in progress and includes detailed engineering of the project. The fourth and fifth stage will include project execution and monitoring respectively.

The 24,200 ton topside of the Brent Delta platform will be lifted in a single lift – the heaviest lift ever to be carried out at sea. Measuring 300 meters from the seabed to its highest point, the Brent Delta platform stands as tall as the Eiffel Tower.

The lifting process is expected to take only a few seconds, and will be done using the Allseas’ vessel Pioneering Spirit. The twin-hulled 382 meter (1,253 foot) Pioneering Spirit (formerly Pieter Schelte) is a dynamically positioned vessel for single-lift installation and removal of large offshore oil and gas platforms, and the installation of oil and gas pipelines. It can lift 48,000 tons in a single lift.

Giant clamps that will be added to the legs prior to the lift are under construction. Shell is using specially-adapted technology to remove the small portion of oil trapped at the top of the cells on Delta. Large baseplates, almost 2.5 metres in length, have been installed 80 metres under the sea onto the top of Delta’s storage cells, each of which stand 60 metres tall by 20 metres wide.

The removed topsides will then be transported to the Able Seaton Port (ASP) facility at Teesside for dismantling, recycling and disposal. Wood Group has been contracted to undertake the decommissioning, including integrity management, safe shutdown, hydrocarbon cleaning and disconnections.

Allseas also has a contract from Shell to remove the Bravo and Alpha topsides.

A history of innovation at Brent

Late 1970s: Three enormous gas compression modules were built to re-inject gas into the reservoir. At the time, these contained the world’s largest offshore reciprocating compressors.

1977: A pipeline from the Brent Field to St Fergus in Scotland was completed. It was the world’s largest single welded pipeline at the time.

Late 1990s: Brent Field undertook what was at the time the world’s largest oil field depressurisation. It remains one of the largest engineering projects ever undertaken in the North Sea.

2000: The Brent Field was externally benchmarked as the highest-performing North Sea field.

Record-breaking production

In the 1980s, the Brent Field was consistently producing over 400,000 barrels of oil equivalent a day – enough oil in a year to provide energy to over 12 million homes. In 1982, production peaked at 504,000 barrels of oil per day. The one billionth barrel of oil was produced from the Brent Field in March 1987.

By the early 1990s, the Brent Field was supplying 13 percent of the U.K.’s oil and 10 percent of the U.K.’s gas needs. In the mid-1990s, Shell started an ambitious project to convert the field from a majority of oil production to one focused predominantly on gas. This cost £1.2 billion and provided jobs for more than 3,000 people.

By 2001, the Brent Field was yielding record levels of gas production; 25.5 million cubic metres per day. Its total oil and gas production reached 700,000 barrels of oil equivalent per day.