New Resistance Software Boosts Power Saving Potential

By Adam Larsson and Vladimir Shigunov of DNV GL

Ships are traditionally designed and optimized for calm-water performance. In reality however, ships will mainly be operating in moderate seaways which reduce speed or increase power requirements. This added resistance from waves is particularly important for full, slow ships, such as bulkers and tankers. For these ships, resistance in waves may be, on average, as much as 20 percent greater than calm-water resistance over a typical trade.

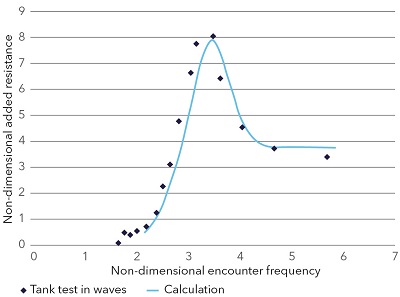

Until recently, the accurate calculation of added resistance (more precisely: added power requirements) in waves has been considered impossible or at least impractical. Instead, global margins have been employed, based on experience and hoping for the best. But new simulation tools developed by DNV GL Maritime Advisory could change the game, giving a much more realistic and accurate picture of added resistance in waves. The software considers 3d seakeeping and is accurate down to wave lengths of 10 percent of ship length, the lowest reasonable value to be of practical importance. Validation against dedicated model tests shows excellent agreement.

Until recently, the accurate calculation of added resistance (more precisely: added power requirements) in waves has been considered impossible or at least impractical. Instead, global margins have been employed, based on experience and hoping for the best. But new simulation tools developed by DNV GL Maritime Advisory could change the game, giving a much more realistic and accurate picture of added resistance in waves. The software considers 3d seakeeping and is accurate down to wave lengths of 10 percent of ship length, the lowest reasonable value to be of practical importance. Validation against dedicated model tests shows excellent agreement.

This break-through has implications well beyond the small circle of seakeeping experts. Accurate prediction of added power in waves is a keystone technology for smarter decisions in ship design and operation. Possibly the most important being an extension of currently used hull optimization techniques. These more realistic calculations will allow hull form design for in-service conditions (and not just for calm water). In one of the first uses of the new simulation tools, a recent DNV GL case study demonstrates the potential for further fuel savings if performance in waves is considered in hull design, especially for bulk carriers and tankers.

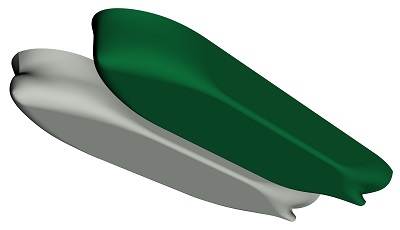

Two hull variants of a Handymax bulk carrier were investigated: one with a conventional bulbous bow, one with a straight bow profile. The assessment considered a typical trade and a simplified operational profile with two load conditions (fully loaded and in ballast) and two speeds (service speed and slow steaming). The design with the straight bow contour reduced average fuel consumption per year by 3 percent.

Two hull variants of a Handymax bulk carrier were investigated: one with a conventional bulbous bow, one with a straight bow profile. The assessment considered a typical trade and a simplified operational profile with two load conditions (fully loaded and in ballast) and two speeds (service speed and slow steaming). The design with the straight bow contour reduced average fuel consumption per year by 3 percent.

There are several other services which could benefit from the new capabilities the newly developed advanced simulations offer.

• Power margins – The current trend towards lower design speeds has important side effects. A sea margin of 15 percent is typically written into design specifications, without putting much thought into this value. However, with decreasing speed the calm-water resistance decreases more rapidly than the added resistance in waves. Higher sea margins should then be selected. The correct sea margin could and should be selected based on simulations, considering hull shape and intended trade. Similarly, advance knowledge of added power requirements for a given seaway could guide the selection of operating points for propeller and engine.

• Performance monitoring – Monitoring has gained importance in a tighter business environment where contractual partners strive for more transparency and performance guarantees. Better corrections for ambient conditions lead to less scatter in performance monitoring and faster insight.

• Routing – Route optimization considers weather forecasts and added power requirements as function of seaway, speed and course. The usefulness of routing advice depends on the accuracy of the predicted seaways and the predicted added power requirement.

The improved simulation capabilities have the potential to further improve decision support systems in design and operation, leading to smarter and greener shipping.