Fuel Switching Fix Leads to Engine Room Fire

The NTSB has completed an investigation into an engineering space fire on the container ship Gunde Maersk, and has determined that repairs intended to solve problems with fuel switching were to blame for the blaze.

On November 25, 2015, the Gunde Maersk's three auxiliary generators began to leak fuel when switching over to ultra-low-sulfur diesel.

Fuel leaks are a known problem when switching from HFO to diesel, and the engineering crew set about making repairs. The third engineer and an unlicensed crewmember replaced the O-rings in the fuel supply lines to the injection pumps on all three auxiliaries, and they completed a brief test after each job. They followed normal written procedures prior to starting work.

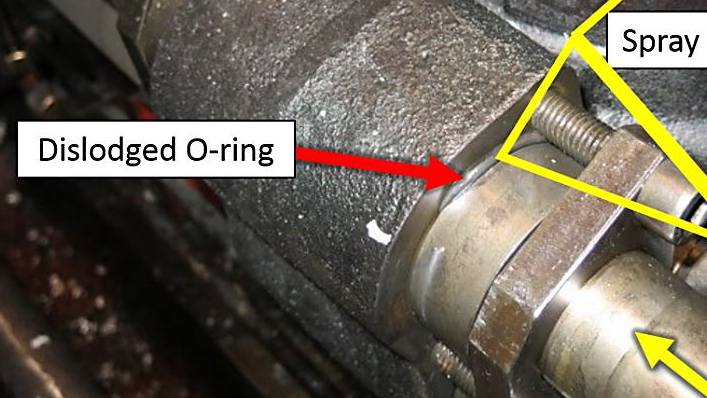

On December 8, a week after the last repair was made, the Gunde Maersk was leaving her berth in Port of Seattle to head to Busan. Minutes after getting under way, the O-ring seal on one of the number 1 auxiliary's fuel supply lines failed, spraying a mist of diesel onto the exhaust side of the engine. The fuel caught flame, setting off the fire alarm and triggering an automatic shutdown of the number 1 auxiliary. Fire dampers closed automatically. By the time a firefighting crew entered the space – 15 minutes after the start of the fire – the blaze was already out.

Another auxiliary generator took up the load, and while the ship did not lose power, the event created an "error in the high voltage electrical system and integrated automation system (IAS), causing a loss of control of the main propulsion engine fuel pumps."

The IAS responded by shutting down the main engine. The crew could not restart it immediately; they anchored and called for tug assistance.

NTSB investigators, working with the Coast Guard, found that the O-ring in the leaky joint had been pushed out to one side when subjected to pressure. They suggested that the likely reason for the failure was improper tightening of the fitting.

In addition, NTSB found that lack of a well-defined testing procedure for the repair may have been a contributing factor.

While the fire was brief, and could have caused more damage than it did, NTSB said that repairs to the engineering space cost nearly $400,000 dollars – funds that could have been saved, the agency asserts, if a full set of procedures had been defined and followed.