Coast Guard Type Approval Applications Roll In

Earlier this week, the U.S. Coast Guard Marine Safety Center (MSC) has received an application requesting U.S. Coast Guard type-approval for the Optimarin ballast water treatment system. This has now been followed by an application from Alfa Laval.

The news follows that of the ratification of the IMO Ballast Water Management Convention, with Finland’s signature pushing it past the 35 percent of combined global tonnage (from at least 30 contracting states) needed to bring it into force.

“The receipt of the first application for a Coast Guard type-approved ballast water management system represents an important milestone for the future of protecting our nation’s waterways from the spread of invasive species,” said Capt. John Mauger, commanding officer of the MSC.

The U.S. Coast Guard type-approval process and application is described in 46 CFR 162.060. This process requires the independent laboratory to oversee and report on a full suite of testing to demonstrate compliance with the design and performance standards specified in the regulations.

Both manufacturers that have submitted applications use UV treatment to neutralize organisms via the DNV GL testing facility, and the applications have been accepted on the basis of testing conducted in accordance with the current regulations – that is viral staining rather than the most probable number (MPN) method.

In December 2015, the U.S. Coast Guard announced their preliminary decision to not accept the MPN method for the verification of the performance of ballast water treatment systems. The Coast Guard’s reason for rejecting the MPN method is based on the notion that the MPN method does not measure if an organism is “living,” but rather if it is “viable,” which is not in accordance with the Coast Guard ballast water discharge standard which requires less than 10 living organisms per milliliter in discharged ballast water.

The MSC’s stated goal is to review and reply to each submittal within 30 days of receipt.

Alfa Laval

After successful completion of land-based tests with marine, brackish and fresh water – all using the current ballast water treatment system design – a test report package for PureBallast was finalized by the independent lab DNV GL and filed with the U.S. Coast Guard for the PureBallast 3 family.

The company completed all tests of PureBallast during summer this year. The tests were performed using the CMFDA/FDA (staining) method approved by the U.S. Coast Guard and were conducted at DHI in Denmark. It is significant to note that the testing involved the same hardware, power consumption and flow as the IMO-approved version of the PureBallast 3 family.

The company completed all tests of PureBallast during summer this year. The tests were performed using the CMFDA/FDA (staining) method approved by the U.S. Coast Guard and were conducted at DHI in Denmark. It is significant to note that the testing involved the same hardware, power consumption and flow as the IMO-approved version of the PureBallast 3 family.

Meanwhile, Alfa Laval continues to support the efforts to validate the MPN method, which the company sees as a preferable alternative to the CMFDA/FDA method for UV treatment systems. Alfa Laval’s decision to proceed with CMFDA/FDA testing was based on the importance of providing customers discharging in U.S. waters with a type-approved solution as quickly as possible.

Optimarin

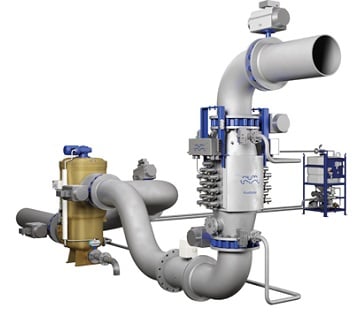

Optimarin’s U.S. Coast Guard testing was conducted by DNV GL at the NIVA test facility in Norway, and on seaboard tests, with the pumps on the Optimarin Ballast System (OBS) running at full treatment rated capacity.

As well as satisfying all IMO and USCG requirements, OBS is certified by a comprehensive range of classification organizations, including DNV GL, Lloyd’s, Bureau Veritas, MLIT Japan, and American Bureau of Shipping.

Optimarin has currently received orders for around 500 of its market proven systems, which utilise a combination of filtration and powerful 35kW UV lamps to treat ballast water without the need for chemicals. Of these units 280 have been installed worldwide, with close to 100 retrofits, fitted in tandem with global engineering partners Goltens and Zeppelin.

Recent orders include ten units for Atlantis Tankers, 15 systems for Vard Group, three for Saga Shipholding (adding to an additional 26 systems already installed on its fleet), two for Solvang, and a frame agreement with Carisbrooke with the potential to encompass retrofits on 46 bulk and multipurpose vessels.

Sales for the year are up by close to 200 percent.